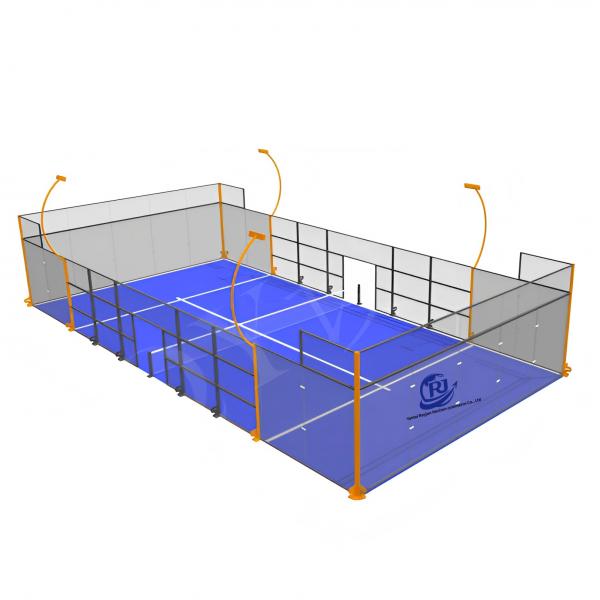

Installation of the Structure and Glass Panels

Uneven surfaces make it challenging to assemble the court structure and securely attach the glass panels.

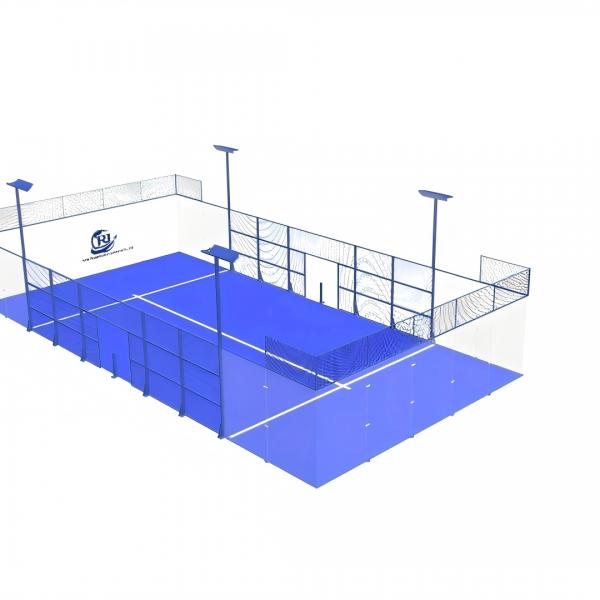

Water Drainage

An improperly leveled surface can cause poor drainage, leading to the formation of puddles during rain, which can delay play and cause further damage over time.

Quality of Play

Irregular surfaces can significantly affect the ball's bounce, resulting in an inconsistent playing experience for users.

To prevent these issues, it’s essential to focus on the slab's quality and construction. In this guide, we’ll walk through the recommended steps for creating a semi-polished concrete slab that is ideal for outdoor padel courts.

Recommended Concrete Base for Outdoor Courts

For an outdoor padel court, particularly one that lacks nearby paving or drainage systems, we highly recommend a semi-polished concrete slab. This type of slab is favored for its durability, cost-effectiveness, and quicker installation.

Key Specifications for the Semi-Polished Concrete Slab:

Lateral Slope: The slab should have a maximum lateral slope of 0.5% to facilitate optimal stormwater drainage. A gentle slope helps direct rainwater away from the court area and reduces puddling.

Surface Finish: The concrete should be semi-polished to provide the right balance between durability and traction. This will ensure the turf does not slip during play while still offering a smooth surface for ball bounce.

Semi-Polished Concrete Padel Court Slab Construction

The slab construction for a semi-polished padel court involves the following minimum specifications:

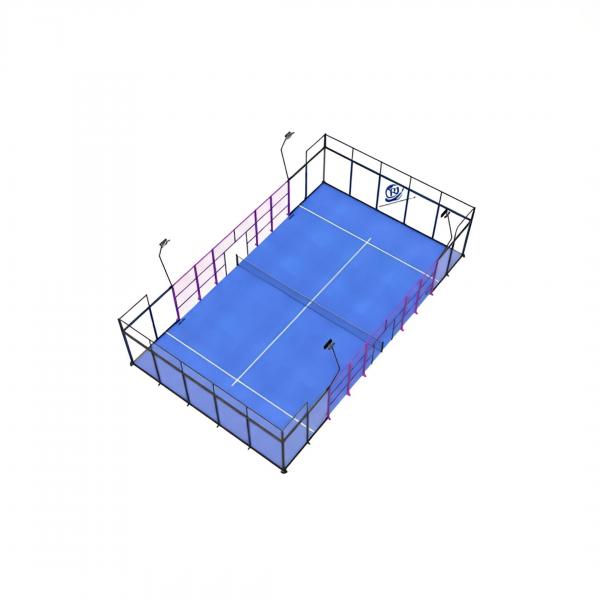

Dimensions:

Length: 21 meters

Width: 11 meters

Construction Process:

Perimeter Formwork: A strong perimeter formwork is used to frame the slab, ensuring that the concrete stays in place and maintains the correct shape throughout the curing process.

Reinforcement: The slab should include 6mm reinforcement mesh or fibers to enhance the slab’s strength and prevent cracks over time. This is crucial for providing a solid foundation that will support the court structure.

Concrete Mix: Use HM-25/20MM concrete, which is a high-quality mix that provides excellent strength and durability. The slab thickness should range between 15 to 20 cm depending on the site’s soil conditions and load requirements.

Slab Flatness and Leveling: Ensure the slab is perfectly flat and level. Even small imperfections can affect the stability of the court’s structure and the quality of play.

Slope Considerations for Drainage:

If a slope is needed for water drainage, it should be less than 0.5%. The slope should be designed to lead the water toward one side of the court, where a proper drainage system can efficiently channel the water away.

Surface Finish and Polishing Process

After the slab is poured and has cured, it’s time to focus on the polishing process to achieve the desired semi-polished finish. The power trowel (also known as a “helicopter”) is used to achieve the right level of smoothness and traction.

Initial Grinding:

Start with diamond grinding pads to smooth the concrete and remove any roughness. This ensures a level surface before the polishing process begins.

Progressive Polishing:

Gradually increase the grit of the diamond pads—starting from lower grits (such as 30-50) and moving toward higher grits (100-200). The higher the grit, the smoother and shinier the finish, but for a semi-polished surface, you don't need a mirror-like finish. Aim for a slightly textured surface that still offers good ball bounce and non-slip traction.

Final Polishing:

Apply higher-quality diamond polishing pads to refine the surface and give it a semi-polished appearance. The goal is to achieve a surface that feels smooth to the touch but still has some texture for optimal traction during play.

Additional Tips for a Successful Installation

Sealing: After polishing, it's advisable to apply a concrete sealer to protect the slab from water damage, dirt, and wear. The sealer should be breathable and provide an anti-slip surface to maintain player safety.

Regular Inspection: Periodically check the slab for surface wear or cracking, especially around high-traffic areas. If any issues arise, address them quickly to maintain the quality of the playing surface.

Conclusion

The semi-polished concrete slab is an excellent choice for outdoor padel courts. By ensuring proper flatness, reinforcement, drainage, and a non-slip finish, you create a durable, long-lasting surface that enhances both the structure installation and gameplay experience. Careful attention to detail during the construction process will guarantee a high-quality court that players can enjoy for years to come.